We never tire of emphasising it, but pliers are truly versatile tools that can be used in a wide range of applications, be it in industry, mechanics, electronics, electrics, plumbing, heating, air conditioning or even in the home. What are their basic components and how do they contribute to functionality? Here we take a detailed look at the different body parts of pliers, from their tips to their handles.

1. Point/Tip: Precision in action

The tip of a pair of pliers is the foremost end of the tool and is often pointed. It is used to perform precise and targeted grips, whether when holding small parts or gripping into narrow areas that are inaccessible to other tools. It can be anti-twist or flexible, depending on the purpose of the specific pliers.

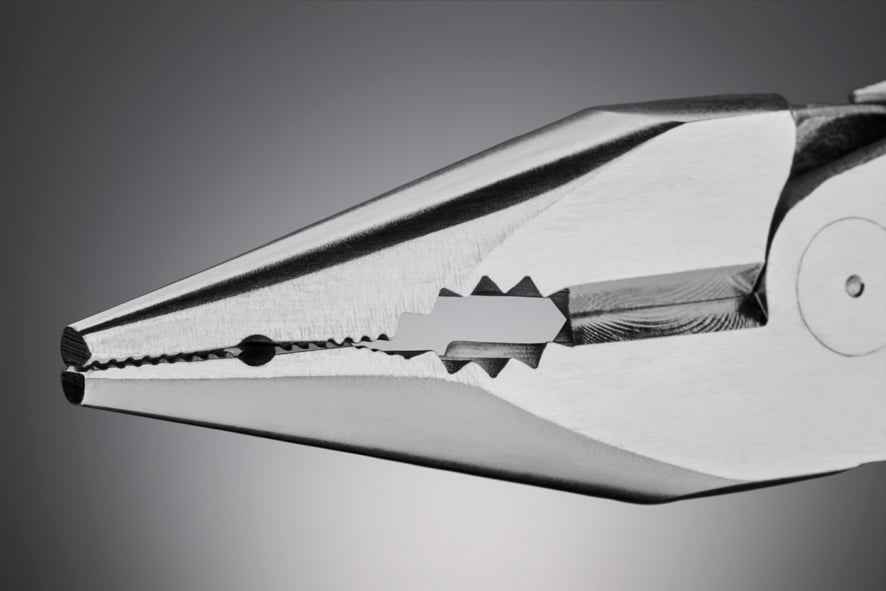

2. Gripping surface: The crucial contact

The gripping surface is the area of the jaws that touches the material to be held. It can be smooth or serrated, for example, to ensure a secure grip, especially on smooth or slippery surfaces. The texture of the gripping surface varies depending on the intended use of the pliers, from smooth surfaces for delicate materials to more aggressive profiles for solid materials. We have covered the different types on KNIPEX pliers here.

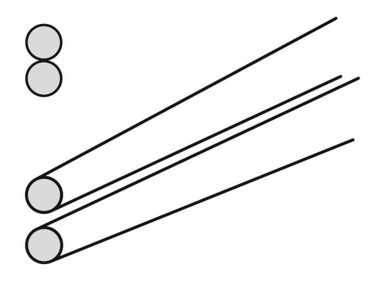

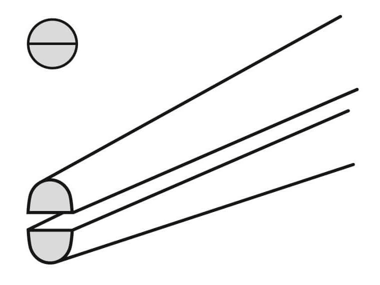

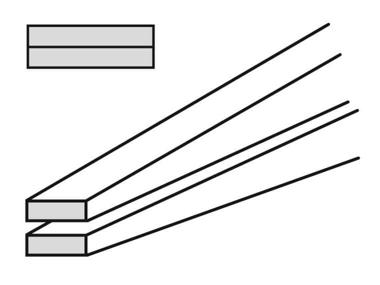

3. Burner port: Well recessed for reliable hold

A striking feature of many pliers is the so-called burner port, a recess in the jaw that is either oval or square in shape. This burner port is usually profiled, i.e. provided with teeth that serve to ensure a firm bite on the workpiece and a reliable grip.

The term "burner port" may seem unusual at first glance, but it stems from the original use of the tool. In the past, pliers with this recess were often used to change the nozzles of welding torches or welding burners. The burner port had the function of reliably gripping the hot burner nozzle and unscrewing it. Nowadays, the use of pliers has evolved, but the term "burner port" has remained to describe this characteristic feature.

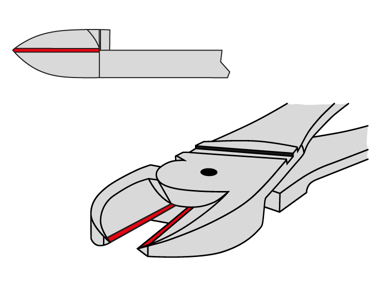

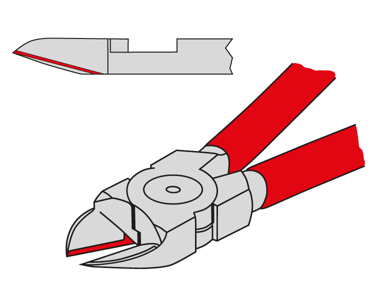

4. Cutting Edge: Precision and power

The cutting edge is a sharp area on the jaws of the pliers that is used to cut materials such as plastic or metals. It is often hardened to ensure a long service life and high cutting performance. The quality of the cutting edge is crucial for the efficiency and precision of the pliers. We have provided detailed information about the different types of cutting edges on KNIPEX pliers here.

5. Jaws: The workhorses

The jaws of a pair of pliers are the main elements that enclose the material to be gripped. They are often robust and resistant to wear in order to fulfil their function for a long time, even with intensive use. The shape of the jaws varies depending on the application, from straight jaws for larger surfaces to angled jaws for hard-to-reach areas. You can find out which jaw shapes we offer at KNIPEX here.

6. Flank: Stability and support

The flank of the pliers is the opposite side of the jaws and provides stability and support during use. It is often reinforced to prevent bending or deformation during use and to provide the user with a firm base to apply force to the material being worked.

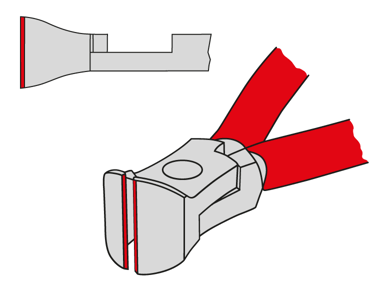

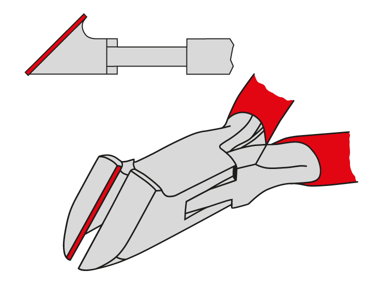

7. Joint: The connection of force

One or perhaps the key component of many pliers is the joint. This element forms the connection between the handles and the jaws of the pliers and enables the tool to be opened and closed. Although it may seem simple at first glance, the joint plays a special role in the functionality and durability of the pliers.

The joint must have sufficient strength to withstand the forces exerted on the pliers during use, but at the same time be flexible enough to ensure smooth movement. Without a robust, well-designed and precisely manufactured joint, the tool's functionality, durability, performance and handling would be severely affected. It is the connection of force that makes the pliers an effective and reliable tool that is indispensable in numerous applications. You can find out more about the joint types at KNIPEX here.

8. Handles: Comfort and control

The handles of a pair of pliers are the part that is gripped by the hand to operate the tool. They are often ergonomically shaped to provide comfort during use and may be coated with non-slip materials to ensure better control and stable hold, especially in wet or oily conditions.

At KNIPEX, we offer different handle variants to meet the different preferences and needs of users. You can choose between bare, plastic-coated, various multi-component handles and two versions of insulated VDE handles.

Conclusion

Overall, the different body parts of a pair of pliers work together to create a powerful and versatile tool that can be used in a variety of applications. From the precision of the tip to the stability of the handles, each component plays an important role in ensuring efficient and reliable performance.

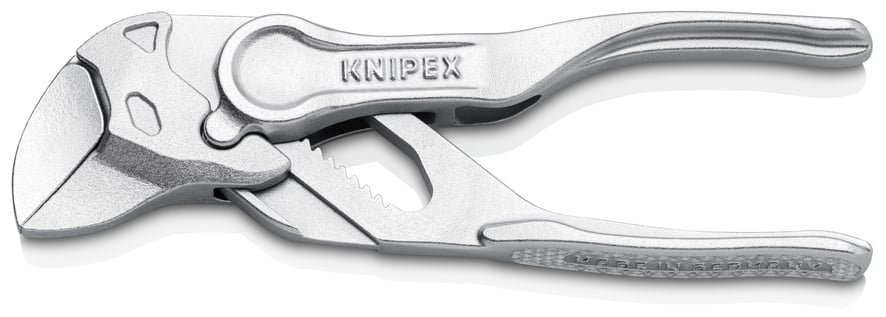

Featured products: 03 02 180 Combination Pliers - 86 04 100 Pliers Wrench XS - 87 01 250 KNIPEX Cobra - 08 25 185 Needle-Nose Combination Pliers - 78 13 125 ESD Electronic Super Knips - 70 06 140 Diagonal Cutter - 70 07 180 Diagonal Cutter