We at KNIPEX have been producing pliers since 1882 and over the years we have accumulated a wealth of knowledge that we would like to share with you. Today we would like to immerse you in the fascinating world of jaw shapes of gripping pliers and show you how choosing the right jaw shape can make your work effortless and efficient.

The jaws play a crucial role in the functionality of grippers. They can be used for gripping, guiding, holding, bending, cutting or even combined for multiple purposes. The choice of jaw shape depends on the intended use, and KNIPEX offers an impressive variety of options to fulfil your requirements.

Gripping pliers: Flat, flat-round and round

KNIPEX offers a wide range of gripping pliers that differ in the shape of their jaws. Here are the main categories:

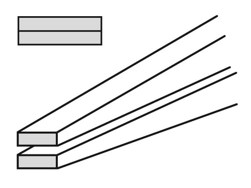

- Flat nose pliers: These gripping pliers are perfect for gripping flat objects and for holding workpieces. The flat jaws enable even pressure to be distributed, which is particularly important for delicate materials.

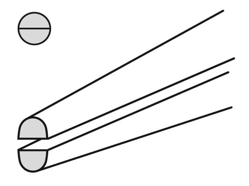

- Snipe nose pliers: The snipe nose pliers combine the advantages of flat nose pliers and round nose pliers. They are ideal for gripping workpieces with different shapes, especially those that have a certain amount of roundedness.

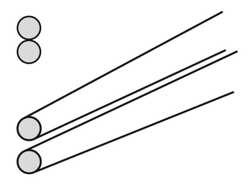

- Round nose pliers: These gripping pliers are perfect for round workpieces and wires. The round jaws ensure a secure hold and minimise the risk of damage to the materials.

In addition to these main categories, KNIPEX also offers special shapes that are suitable for specific applications such as assembly, fitting or mechanics. Choosing the right jaw shape also depends on your available working space and the intended use.

Gripping surfaces: Smooth, serrated or cross serrated

The gripping surfaces of the jaws are just as important as the shape itself. KNIPEX offers jaws with different surface structures that can be selected depending on the material to be processed and the intended use:

- Smooth: Smooth is ideal when it comes to protecting sensitive surfaces. These gripping surfaces leave no marks and are perfect for fine work.

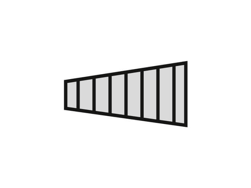

- Serrated: The serrated gripping surfaces offer an improved grip and are particularly effective when gripping workpieces that could easily slip.

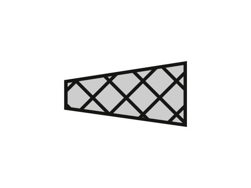

- Cross-serrated: Cross-serrated gripping surfaces are a combination of the two. They offer an even better grip and are well suited to a wide range of materials.

Conclusion

With the different jaw shapes and gripping surfaces KNIPEX offers, you can be sure to find the right tool for your needs. Choosing the right pliers can make the difference between a frustrating task and a smooth job.

Whether you want round, smooth jaws for a gentle grip or flat, cross-serrated jaws for a stable hold - you'll find what you're looking for here.

At KNIPEX, we place great emphasis on quality, precision and ease of use, and the variety of jaw styles is just one example of this. We hope this insight into the world of gripping pliers and their jaw shapes has helped you choose the right tool for your next job.

.png?width=1200&length=1200&name=MicrosoftTeams-image%20(43).png)