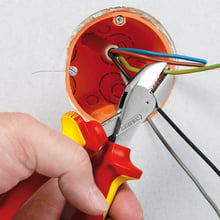

At the heart of every pair of pliers is their joint, which skilfully transfers the force from the handles to the cutting edges or jaws. At KNIPEX, we highly value the art of joint design and use different types of joints depending on the specific requirements of the pliers.

The joint axis, as a pivot point, can take on various forms - be it a screw, rivet or forged bolt. This choice depends on the load that the pliers have to withstand. To ensure that pliers with a fixed pivot point rotate smoothly and without play, the precise manufacture of all joint surfaces is crucial.

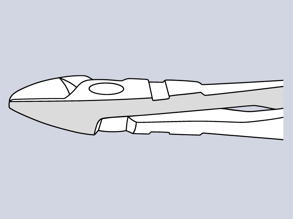

Lap joint: Robust and strong

The lap joint, which is used for pincers, nippers and high-leverage diagonal cutters, for example, is characterised by the fact that both halves of the pliers rest on each other without any elaboration. This enables a particularly robust design of the pliers handles, which is an advantage in areas with high loads.

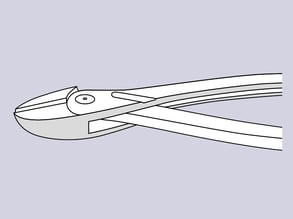

Single joint: Refined design for smooth movements

With the single joint, on the other hand, both halves of the pliers are cut in half and can therefore be inserted into each other. The smooth outer sides in the riveting area give the pliers a smooth movement and contribute to an appealing aesthetic. This can be found, for example, on our 70 diagonal cutter.

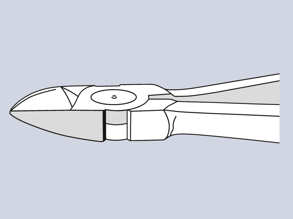

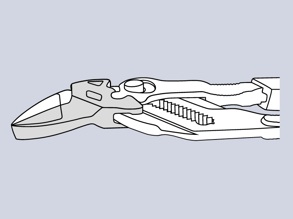

Box joint: Maximum load capacity for demanding tasks

Pliers with box joints are characterised by their particularly high load capacity. Here, one handle of the pliers is pushed through the slotted second handle, while a hinge pin mounted on both sides ensures a secure connection. This design ensures precise guidance of both handles of the pliers, even for demanding tasks. Examples of this are the KNIPEX X-Cut® or the KNIPEX TwinGrip. The TwinGrip and the KNIPEX Cobra®, however, are also examples of the following joint.

Slip joint: Flexibility in the adjustment

Slip joints allow the jaws to be optimally adapted to different workpiece sizes. The jaw opening can be enlarged or reduced by moving the jaws towards each other. A locking mechanism is unlocked or a spring-loaded bolt is released to allow adjustment. Water pump pliers and pliers wrenches are classic examples of these flexible pliers joints.

Conclusion

In the world of KNIPEX, the joint is more than just a technical detail - it is the crucial link between the user and the tool.

While lap joints are particularly common on pliers, which need to be very robust and powerful, single joints ensure a particularly smooth action. Box joints are particularly durable and precise. Slip joints, on the other hand, score points in particular due to their ideal adaptability to the required capacities.